4 Ways To Determine The Correct Fuel Consumption

The 4 methods of determining consumption are:

1. fleet monitoring

2. consumption measurement drive

3. consumption simulation on the computer

4. test bench measurement

You need to know your correct fuel consumption for many purposes.

Certainly, planning and optimizing fuel costs are among the most important ones.

Perhaps you want to compare vehicles with each other?

Do you want to find out which vehicle has better fuel economy?

To arrive at accurate conclusions and make informed decisions, the fuel consumption values must reflect real-world usage in day-to-day business operations.

Determining the correct fuel consumption is not easy at all. Believe me!

Quite in contrast to the pure task of calculating the fuel consumption value itself, which is pretty simple.

The article: 5 Ways To Calculate Fuel Consumption (incl. calculator) provides comprehensive information on the various types of fuel consumption values and their calculation methods.

🤔

Modern trucks display one or more fuel consumption values on the dashboard.

You can look them up at any time and you don’t even have to do the math yourself.

What’s complicated about that?

Well, before you start working with fuel economy figures, you should ask yourself the following questions:

- How big is the scatter and the accuracy of your value?

- Under what conditions was the value measured?

- If you want to compare several fuel consumption values, are they comparable?

- If you want to compare your fuel consumption value with information from other sources, such as journals or magazines, do you know enough details of how they have been derived?

The difficulty lies in the quality and availability of the input data for the calculation.

The input values are typically the root cause for the scatter and the non-comparability of calculation results.

This article will introduce you to different ways how to find out the correct fuel consumption. Each method has its advantages and disadvantages, which you will learn about here.

Knowing this, you will be able to choose the right method for your particular use case. You will learn how to assess the consumption values and how to work with them.

In my blog, I go into detail about this problem in many articles. You can find all of them in the category: Determine consumption.

So let’s jump right in:

Before we start with the measurement methods, I want to go over the important criteria that should be considered when determining fuel consumption.

Fuel consumption measurements have errors.

In order to recognize when the values have a large error, you should know in which order of magnitude the consumption is to be expected.

If you work continuously with your consumption values, you will get a feel for the magnitude of your numbers.

To begin with, I’ll give you the range of heavy truck fuel consumption as a starting point.

What is the fuel consumption of a truck in Europe?

The average fuel consumption of European trucks on the road is in the order of 25 to 35 l/100 km, depending on use case, payload and driving conditions. The instant consumption varies between 0 (downhill) and well over 100 l/100 km (severe uphill). When transporting extra heavy loads and in demanding off-road applications, an average diesel consumption of over 50 l/100 km is to be expected.

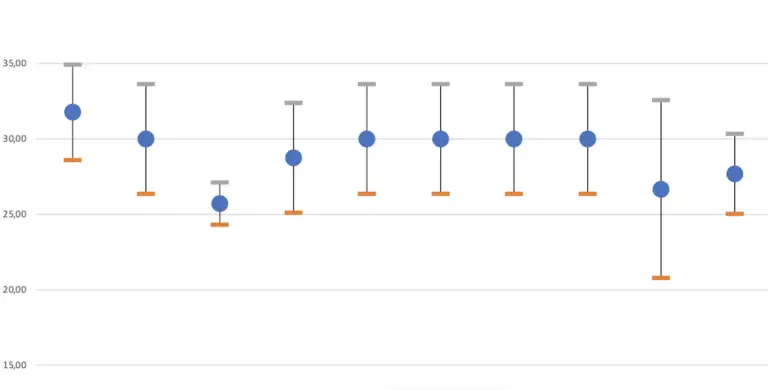

As you can see, the scattering of the values is quite big. It is therefore not correct to calculate just one single value and assume that it is representative of the whole operation of the truck. More data must be considered to come to a reliable conclusion.

If you want to learn more about the root cause of this scatter, you should read my article: “Why does fuel consumption vary? (a simple explanation)”

Relative fuel consumption requires two measurements.

For vehicles, we use relative fuel consumption in liters per 100 kilometers or miles per gallon.

For calculating the correct relative fuel consumption, two input values are needed:

The fuel volume consumed,

and distance driven.

Both values must be available in the correct quality and format.

If this is not the case, then the values need to be measured. (That’s, what we talk about today)

The quality of the input data determines the accuracy of the results.

When I talk about measuring diesel consumption, I’m actually talking about two different measurements.

One is a volume measurement and the other is a measurement of a distance.

They each require very different measuring tools and procedures.

The input data are measured, and the fuel consumption is then calculated using the input data. That’s the way it works.

Both measurements are not exact by nature.

Every measurement has errors. This is inevitable.

It is therefore important to know how big the errors could be and where they occur. Then you can decide whether they are acceptable or not.

In the article: The hidden inaccuracies in fuel consumption measurement, you can read more on this matter.

Every measurement method has its own peculiarities that need to be known and mastered when it comes to measurement errors.

Influencing factors must be taken into account.

To draw accurate conclusions from fuel consumption values, it is important to consider the corresponding boundary conditions that are linked to each consumption value.

Each measurement method has its own way of dealing with the influencing factors.

Therefore, we will also examine the pros and cons of each measurement method in this context.

When working with fuel consumption, simply knowing the fuel consumption value is not sufficient.

It is also crucial to understand the influencing factors that were present when obtaining the respective consumption value.

As you may have observed from your own experiences, fuel consumption values are never exactly the same due to the presence of influencing factors that cause fuel consumption to be higher or lower.

It’s important to closely examine the range of fuel consumption values, as it can indicate the level of significance of those values.

You can find detailed instructions on how to do this in my article “How to assess the distribution of fuel consumption values?”

The 4 methods for determining fuel consumption are, in fact, 4 distinct approaches to addressing the various influencing factors that can impact fuel consumption

I distinguish these influencing factors into two groups:

Systematic influence factors

The systematic influencing factors always have a predictable effect.

We look for them because they offer reproducible potential for improvement.

Systematic influencing factors are changeable, and changes in these factors consistently affect fuel consumption in the same manner.

While these factors can be modified in principle, this does not necessarily mean that you can control all of them.

Nor does it imply that they can be influenced at any given time.

This results in two tasks:

- First, we need to examine the impact of these factors on fuel economy in our particular use case.

- Second, we need to find out which of the factors we can influence and which we can not.

The factors, which we can influence, are levers for improvement.

We can reinforce the positive factors and suppress the negative factors.

By doing so, we achieve a sustainable fuel consumption improvement.

We need to identify the systematic influencing factors and observe their effects. It’s important to keep this in mind, as we will revisit this concept repeatedly.

When measuring fuel consumption, it’s important to gather and document information about the systematic influencing factors.

Random influence factors

At the same time, we need to deal with the factors that we can not influence.

We need to exclude their effect.

The different measurement methods use different approaches.

Random influencing factors also have an effect on fuel consumption, but they are beyond our control.

Weather and traffic are examples of random factors. As they dilute the results, they need to be somehow eliminated.

Random influencing factors do not offer any potential for improvements, but still need to be considered because they affect fuel consumption and its variability.

Let’s get started by looking into the 4 ways to measure fuel consumption.

Method 1 — Fleet monitoring

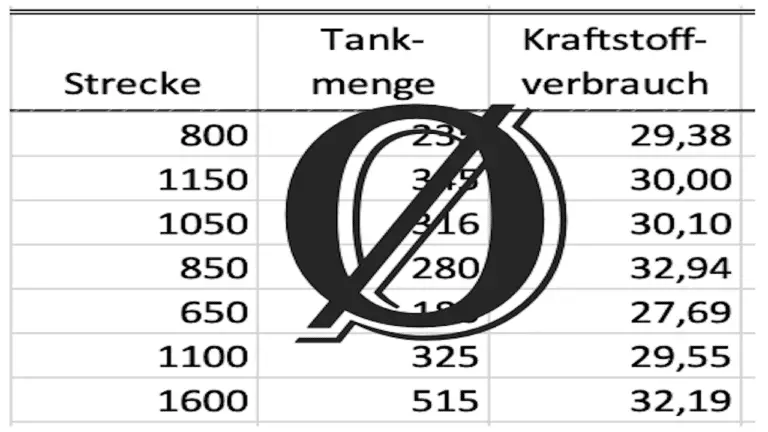

In fleet monitoring, fuel consumption is measured by collecting many individual consumption values of the vehicles within a fleet.

The most important requirement for this method is the availability of a large number of individual fuel consumption values.

For this, you have to drive for a corresponding time or distance, respectively. This method requires some patience.

Therefore, this method fits people running high mileage under normal operating conditions.

In the article “How To Find Out The Fuel Consumption Using Fleet Monitoring”, I explain how exactly to carry out the fleet monitoring method, and how to acquire a representative result, that you can work with.

Anyone can use fleet monitoring, that's the beauty of it.

If you’re one of those who write down the mileage every time you fill up your truck, then you’re already a user of the fleet management method.

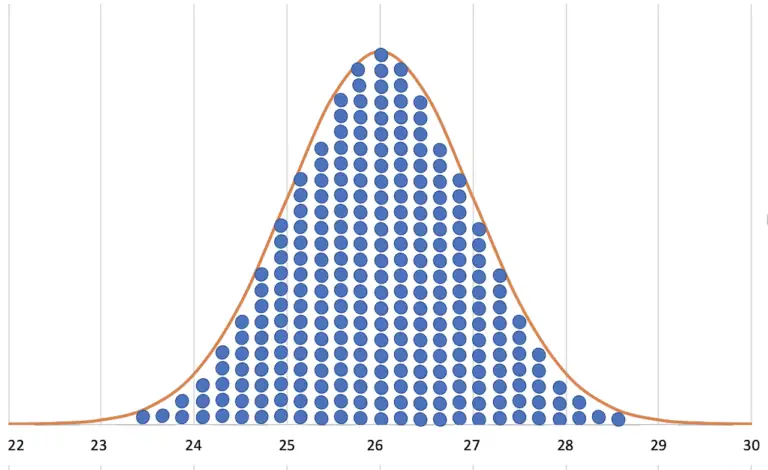

Fleet monitoring is the “method of mass” and requires a sufficiently large number of individual values as input for the calculation of a final representative consumption value. The higher the number of input values, the more accurate the overall result.

You may not be surprised if I tell you that this representative result is called “average consumption”.

You can find more about calculating the average consumption in a separate article s well.

When using fleet monitoring, some important aspects regarding the influencing factors must be considered. If done correctly, you will get an accurate statement.

Dealing with influencing factors using fleet monitoring

The basic assumption of fleet monitoring is that the influencing factors average out and neutralize each other over time and with a large number of consumption values.

However, this approach only works to a certain extent.

As the name suggests, randomness can only impact the factors that are truly random.

In the case of truly random factors, having a large number of consumption values can be beneficial, allowing chance to play its role.

In the article on normal distribution, you can learn about how chance works.

However, the systematic influencing factors are not influenced by chance on the one hand, and on the other hand, they are of interest to us.

They offer the possibility to influence consumption. So you can’t leave these factors to chance, but you have to deal with them intensively yourself.

You can find all articles about fleet monitoring in the fleet monitoring category.

Method 2 — Fuel consumption measurement run

During a fuel consumption measurement drive, the fuel consumption of a specific vehicle is measured.

A consumption measurement drive is the “method of the class”. This method requires extremely precise execution in order to obtain an accurate result.

The method of consumption measurement runs is typically used to check or determine the effectiveness of fuel consumption optimization measures.

If you have attended a training course for consumption-optimized driving, then you have probably already experienced it yourself:

Without being aware of it, you carried out a consumption measurement drive.

Of course, not only the influence of the driving style is measured in this way.

The main area of usage is the evaluation and confirmation of vehicle improvement measures.

If you read in a magazine about a test of a vehicle, you will usually find a statement on the fuel efficiency of the vehicle presented.

With a high degree of probability, this information was determined using the “consumption measurement drive” method.

Can you trust what it says?

Generally yes, because these measurements are done by professionals. However, your fuel consumption would still be different, if you would repeat the measurement.

I’m going to explain in detail what to look out for when making up your mind about whether you can trust such a statement.

Do you want to carry out a fuel consumption measurement drive yourself?

I will write another article that will help you with this project.

Dealing with influencing factors during a fuel efficiency measurement run

Since only very few measured values are created during the consumption measurement drive, chance doesn’t stand a chance.

The trick, that works for fleet monitoring, cannot be used here.

For this reason, it is necessary to meticulously consider each individual influencing factor.

A consumption measurement drive is associated with a considerable amount of effort for preparation, execution and evaluation. It is therefore only used if specific questions have to be answered.

For this reason, you will consider using the results of other people’s measurements. Be it magazines, manufacturer information, or other institutions that do such tests and publish the results.

It is all the more important that you know what to look out for when you trust the results of other people’s measurements.

Method 3 — Fuel consumption simulation by computer

In fuel consumption simulation, the fuel consumption of a virtual vehicle is calculated in the computer using a mathematical model

The virtual vehicle is a twin of the real vehicle for which we want to know the fuel consumption. So the value we get corresponds to the consumption value of the real vehicle.

A consumption simulation is the "method of analytics". A validated mathematical vehicle and driver model is required for this method.

This method is very popular with vehicle manufacturers.

They have the information needed for the calculation, the necessary know-how, and the equipment. (Another group is the companies and research institutions that research and develop such tools.)

For a vehicle developer, this method offers a unique opportunity. He can determine the fuel consumption of a vehicle or the impact of improvement measures before the vehicle even exists in reality.

This saves a lot of time and money. Therefore, the know-how and the equipment for these calculations belong in the repertoire of every vehicle manufacturer.

The quality of the result depends on the quality of the mathematical/physical model and of course also on the quality of the input data.

Mathematical models always have simplifications that reduce accuracy.

The input values, in turn, often have to be determined or at least confirmed by real measurements.

In order to verify the results of the calculation and to further develop the models, consumption measurement runs or test bench tests with real vehicles have to be carried out again and again.

The calculation method must always be calibrated by reality.

Influencing factors in consumption simulation

By using the consumption simulation, all influencing factors can be consciously controlled. This is a unique advantage and disadvantage at the same time. As a consequence, the result is repeatable. But on the other hand, it is synthetic and doesn't reflect real live to the full extent.

There is no randomness in a computer unless you consciously build in a random number generator.

All fuel consumption influencing factors can be set in a controlled manner without exception. This even applies to the behavior of the virtual driver.

This means that even small improvement measures can be isolated and evaluated very nicely.

Due to the controllability of the influencing factors, the results can be compared with each other without restrictions.

However, transferring the results into daily practice is not easy. Chance rules the real world, and the dice roll just the way they want. It requires some effort and some compromises to translate the simulation results into real-world applications.

VECTO is a consumption simulation tool

An example of this method is the VECTO Tool of the European Union (Vehicle Energy Consumption Tool).

The legislator has set it up to evaluate the efficiency of the vehicles of all manufacturers.

You receive these calculated values from the manufacturer together with the papers for your vehicle. That’s a law.

I will go into detail about VECTO in a separate article.

It is important to understand what is and is not reflected in these values.

Why did the legislator in the case of trucks decide in favor of the consumption simulation method?

Well, because the vehicle variance in commercial vehicles is extremely large, it is impossible to do measurements with each vehicle variant sold.

Doing a simulation for every variant is feasible.

The simulation offers the opportunity for a fair comparison of vehicles from different manufacturers.

Both sides, legislators and vehicle manufacturers, have agreed on simplifications in the model, which reduce accuracy but increase fairness.

If everything is done right, the real fuel consumption should actually be better than the VECTO value, because some consumption-saving factors are not taken into account.

But this tool is also constantly being developed and should become more and more accurate over time.

Simulation light for the common people

As you read my articles, you will come across mathematical formulas. These formulas are small mathematical models.

By using these formulas in Excel spreadsheets, I can do calculations and create very simple simulation tools.

The result might not be very accurate, but by trying different input values, I can get information about the magnitude of change in the result.

This gives me a feeling of whether a measure or an influencing factor has a big or a small impact.

I highly recommend this exercise.

Using the formulas to build such small and simple self-service estimation tools gives you a very good insight into the physical correlation of input and result.

Having pointed this out to you, you will recognize these little guessing tools as you read the articles. Watch out for it! In some articles, I am going to provide some for download.

Method 4 — Test bench measurement run

During a test bench measurement, the fuel consumption of a real vehicle is measured on a test bench under controlled conditions.

A test bench run requires a real vehicle and a roller dynamometer, equipped with a sophisticated control system, installed in a building with weather simulation capabilities.

If you have access to such a very expensive test stand, measurements can be carried out quickly and with a high level of repeatability.

A test bench measurement combines the advantages of the consumption simulation and the measurement drive method.

Carrying out such a measurement takes significantly more effort than the consumption simulation, but less than doing a measurement run on the road.

The vehicle needs to be converted into the various states that are to be measured. Therefore, prototype parts need to be manufactured and installed in the vehicle.

Since this is a stationary situation, data logging and measurement sensors in the vehicle can be hooked up to the test stand.

Because it is a measurement with a real vehicle, there is no compromise of a simplified mathematical vehicle model.

The vehicle is real and behaves like a real vehicle.

Influencing factors on test benches

The influencing factors can be controlled during test bench measurements. As a consequence, the results are repeatable. The systematic influencing factors are real and can be isolated and investigated very well.

The environmental influences are consciously controlled on the test bench.

However, the transfer of these measured values into practice has the same difficulty as with the simulation.

Typically, an artificial setting of parameters is used on the test rig, while in practice, chance picks the influencing factors and different consumption values set in.

You might have recognized the discussion on NEFZ cycle (Neuer Europäischer Fahrzyklus, English: New European Driving Cycle) and WLTP cycle (Worldwide harmonized Light Vehicles Test Procedure) for passenger car emission and fuel consumption measurement.

Those cycles are the kinds of artificial settings of parameters, I am talking about.

Since the environmental influences are defined by the legislators, the result is reproducible but not very close to the real world’s consumption.

The intent was, to create something helpful for the engineers, who should get a clear understanding, of what the legislators are looking for when they write their laws and regulations.

That was at least the intention.

As I’m sure you’ve read or heard, some have pushed it beyond legality, which has destroyed trust in the entire industry.

If the specifications are chosen in a way that the test consumption is significantly lower than the real-world consumption, the customers get confused and angry.

Nonetheless, for development purposes, this method offers a great possibility to measure fuel consumption optimization measures, because the results have little scatter.

Road to Rig

Road to Rig is a special way to do the test bench measurement.

The parameters of the test cycle are not set artificially, but are recorded during a fuel consumption measurement drive and then applied to the test rig. By doing so, similarly realistic results can be achieved.

Road to Rig essentially shifts a test drive from the road to the test bench.

It combines the fuel consumption measurement driving test procedure with the test bench measurement procedure.

This is a very interesting method. It provides realistic yet reproducible results.

Using this method, a recorded fuel efficiency measurement run can be repeated many times under the same conditions.

However, acquiring the data requires a significant one-time effort. Therefore, most of the time the focus is on the powertrain data only.

Summary

After you have read this article, I would recommend making yourself familiar with the different types of fuel consumption values and how you can calculate them.

Thanks for the reminder that the temperature is also a huge thing to consider when it comes to doing fuel analysis. I plan to look for a good service like that because I’m interested in looking for a good way to better conserve energy in all aspects when I start a new business. Hopefully, such services will make it easier to make future business decisions as well.

Indeed, the lubricants and their temperature are essential factors in optimizing fuel consumption. Feel free to contact me, if you like to go more in detail on this matter.

Best Regards

Uwe