Hidden inaccuracies in fuel consumption measurement

What can go wrong when calculating fuel consumption?

Well, the input values derived from fleet monitoring can be inaccurate. In this case, the result will be incorrect.

In this article, I will concentrate on how to deal with these deviations in fleet monitoring.

(If you are doing a measurement drive run, you will experience the same problems, but you have to deal with them in a different way. I will come to this later.)

You know the saying: “If you put garbage in, garbage comes out.” (I want to avoid the sh** word)

The calculation itself is straightforward, so not much should go wrong. If you want to check your calculation, you can use this consumption calculator.

But even though you calculated correctly, the result will not be absolutely precise.

The input values for the fuel consumption calculation will always have inaccuracies and therefore cause a deviation in the result.

I will explain these errors in this article. This way, you know what level of accuracy you can expect.

You can avoid or reduce some inaccuracies, others you have to accept.

In the table of contents, you will find the input values at which the errors occur. I would recommend you read everything.

If you are in a hurry, you can also jump directly to the topic that is of most interest to you.

What are the input values affected?

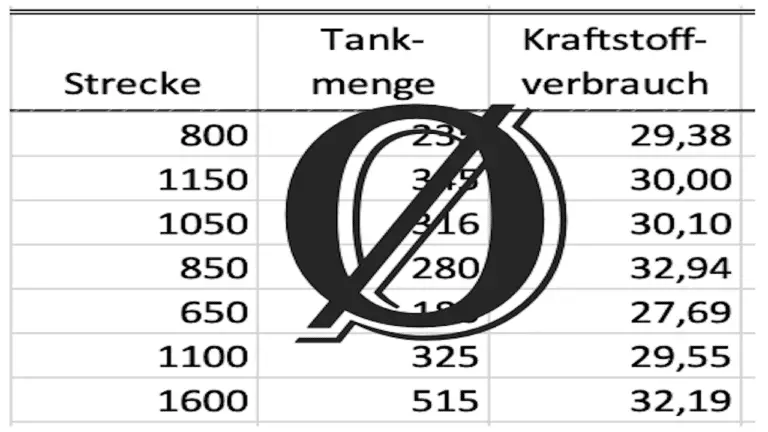

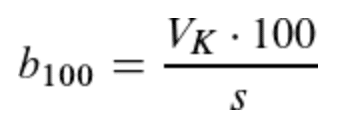

Here again, is the formula for the consumption calculation:

- b100 = relative fuel consumption in l/100km

- VK = fuel volume in l

- s = driving distance in km

You see that two inputs are needed to calculate the relative fuel consumption in liters per 100 km.

If you calculate the fuel consumption yourself, usually you are reading the fuel volume from the gas station and the distance traveled from the vehicle’s odometer.

But when you use the fuel consumption displayed in the display of the vehicle, both values come from sources inside the vehicle.

We will look into both.

The fuel volume from the gas station

What can go wrong when writing off the refilled diesel volume from the fuel pump or the fuel bill?

Well, I’ve proved that a really stupid mistake can happen.

I forgot to write down refueling!

Error factor sloppiness

Of course, that doesn’t happen to you, because you’re very conscientious, aren’t you?

But if you should make this stupid mistake, then it will result in an implausibly good average consumption.

The opposite happens with diesel theft. Here the consumption is implausibly bad.

These are neither random nor systematic errors, and actually, they should not occur at all. Nonetheless, always keep them in mind, they can happen. If you come across implausible values, then it can be due to such stupid errors.

How accurate is the reading from the fuel pump?

The diesel volume that can be read from the fuel pump is sufficiently accurate for fleet monitoring.

Because it is mandated by the legislator that the measuring device in the fuel pump must be checked and calibrated regularly, the tolerance is within limits. This is to prevent cheating on fuel bills.

The accuracy is between 0.2l per 100l (source: Eichamt Sachsen) and +/- 0.5% (source: Wikipedia)

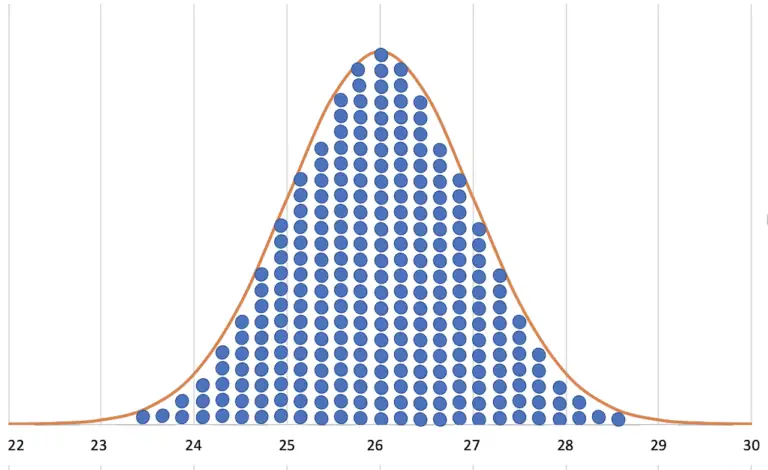

In the worst case, this is 30.15 l/100 km instead of 30.00 l/100 km on the high end or just 29.85 l/100 km on the low end. And that would be the maximum error. The real error itself is normally distributed. It is therefore not very likely that this maximum error will occur with every refueling.

This tolerance is very little compared to the other deviations we’re dealing with. Here we can trust chance. It’ll take care of that little inaccuracy.

Error factor fill level in the fuel tank

Relevant for the fuel consumption is the amount of diesel consumed! Since this cannot be easily determined, we equate the amount of diesel consumed with the amount of diesel refilled.

In order for this assumption to be correct, the tank must be filled to the exact same fill level at the beginning and at the end of each measurement.

So you should always fill up the tanks to the top.

If the tank is “full” then there is still air in the tank. This is a design feature necessary so that no diesel leaks out.

Therefore, it makes a difference how horizontal the chassis is when refueling.

I will explain in a separate article how such a tank works and what to look out for if you really want to refill the exact amount of diesel you have used.

For fleet monitoring, you don’t have to be very meticulous when it comes to being level at refueling. It is enough to simply fill up completely. We consider the inaccuracy as a random factor. We can accept this for the following reason:

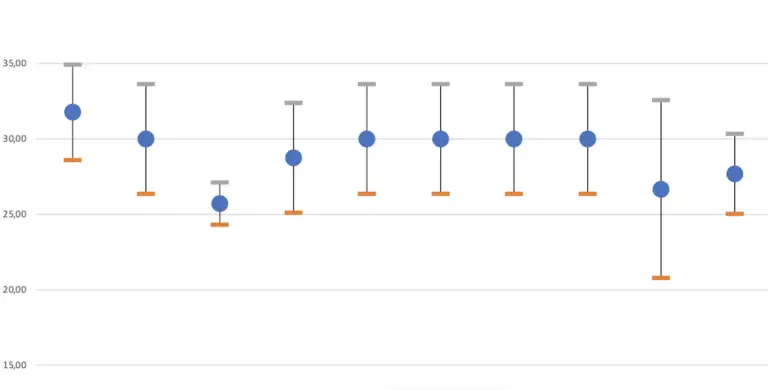

Here is an example of what happens if the refueling quantity does not correspond to the consumed quantity:

The error is neutralized by calculating the average value.

Of course, this only works if you really record every refueling process without gaps!

If your truck has a double tank system, then you should make sure that both tanks are really full. Otherwise, the differences can be very large. That gives blatantly wrong individual values.

What influence does the fuel temperature have?

The chemical energy in the fuel is decisive for the consumption and corresponds directly to the fuel mass, but only indirectly to the fuel volume.

Again, we use a simplification and this affects the accuracy.

Because diesel is a liquid, it’s relatively easy to measure it in liters.

I can still remember my childhood well. My grandfather had a gas station and I often visited him there.

At that time, the petrol was pumped by hand into a glass container at the petrol pump until a line was reached.

Then a lever was thrown, and the petrol ran through the hose into the vehicle’s tank.

To sell 20l petrol, this procedure had to be repeated several times.

The volume of a liquid and its mass are related by a factor, the density.

The fuel density characterizes the relation from mass to volume.

Unfortunately, the density changes with temperature. This leads to the well-known phenomenon that things expand when they get hot.

In order to be able to compare the values with each other, we need always the same diesel temperature.

The good news is that the diesel volume displayed on modern fuel pumps is already temperature-compensated. According to the standard, the measuring device measures the diesel temperature and converts the volume to a standard temperature of 15 °C.

The actual source of error is the temperature of the residual fuel in the diesel tank.

Diesel is used as a coolant for the engine.

Modern engines use fuel to cool down temperature-sensitive engine components.

Significantly more diesel is taken from the tank than is required for injection. The additional diesel bypasses these engine parts and absorbs heat. Its temperature rises significantly.

It then flows back into the tank via the return line.

In the tank, the diesel transmits its heat to the ambient air via the large aluminum tank shell. Then it goes on its next journey through the engine.

If you refuel at the gas station immediately after driving, there will be hot diesel in the tank. It hasn’t had time to cool down yet.

During refueling, the hot diesel in the tank mixes with the cold, new diesel from the pump.

Depending on how much hot diesel is in the tank and how much cold diesel is topped up, the mixed temperature varies.

With the same volume and changing mixing temperature, more or less diesel mass and thus energy fits into the tank.

If you fill up after driving and park the vehicle overnight, you will notice the next morning that the fill level in the tank has dropped. (Without diesel theft!)

The fuel has cooled down, its density has increased and therefore the volume of fuel in the tank has decreased.

The effect on the fuel consumption value is similar to not filling up completely. Just like there, the calculation of the average consumption solves the problem.

I see two ways how you can reduce this problem when you do fleet monitoring:

In the chapter on the consumption measurement drive, I will go into detail about how this differential amount of diesel is calculated. With fleet monitoring, we treat the problem as if the tank isn’t quite full. We leave it to fortuity.

The distance traveled from the odometer in the gauge

For the calculation, we need the distance. It, too, has its pitfalls.

The errors in distance measurement are mostly systematic and not random. Therefore, these effects deserve special attention.

You can read the distance from the speedometer in two ways.

The mileage of the vehicle at the time of refueling is usually entered in a logbook.

You then subtract the mileage from the last fill-up from the current mileage, and you get the distance the truck traveled between the two fill-ups.

If you use a trip meter, you can reset it to 0 every time you fill-up. This allows you to read the distance since the last refueling directly and without calculating.

Measuring directly the distance a vehicle has traveled is complicated. Therefore, a simpler approach is used.

The odometer is actually a rev counter. It converts the wheel revolutions into a distance traveled with the help of the tire circumference.

Well, as a rule, it is not the wheel revolutions that are measured, but the revolutions of the transmission shaft.

The vehicle computer calculates the wheel revolutions from the transmission speed and the final drive ratio. The value of the final drive ratio is stored in the vehicle computer for this purpose.

The speed sensor registers the speed very precisely, that’s not a problem.

To ensure that nobody can tamper with this sensor, the legislator has stipulated for commercial vehicles with tachographs that the sensor must be sealed.

What influence does the tire circumference have?

In order for the calculated distance to be correct, the tire rolling circumference stored in the vehicle must correspond to the reality.

Unfortunately, the tire rolling circumference is not constant. It changes not only when changing tires, but also while driving.

It depends on the following factors:

To ensure that the tire rolling circumference and the axle ratio are correct, the legislator requires a regular rolling test. This test must be carried out at least every two years or after every repair and every tire change (§57b StVZO).

This rolling test is carried out on a roller dynamometer or directly on the road.

In this test, the actual distance driven by the vehicle per wheel revolution is actually measured.

This value is then stored in the vehicle using a diagnostic device.

As a result of this exercise, the vehicle computer knows the true relationship between wheel speed and wheel circumference and can calculate the distance traveled more precisely.

Even if the tire rolling circumference is regularly corrected by the rolling test, it is still not absolutely accurate.

Wheel slip is variable. The more drive torque the tires have to transmit, the greater the slip. As a result, the distance is actually shorter than measured.

Fortunately, the remaining influencing factors are random, so we can let Grandfather Coincidence help us.

You took care of the systematic factors via the roll-off test.

But you should pay special attention to the tread depth. This can change significantly within two years and thus cause a considerable error that could overwhelm the coincidence.

I don’t think I need to mention the fact that the tire pressure has to be corrected regularly. This should go without saying, otherwise you have a much bigger problem than just an incorrect consumption calculation.

What influence does the speed tolerance have on the distance?

There is another interesting relationship that you should know::

The interest of the legislator is actually not in the distance, but in the speed that is recorded in the tachograph.

This can easily be calculated from the distance covered and the travel time.

However, there is a special regulation for driving speed.

The driving speed displayed must never be less than the actual driving speed.

If the speed reading on your speedometer matches the speed limit, you certainly won’t get a speeding ticket. You are max as fast as shown.

Since the distance is in the numerator in the speed formula, it must always have a plus tolerance so that the speed also goes into the plus.

A plus tolerance in the distance measurement leads to a minus tolerance in fuel consumption because the distance is in the denominator of the consumption formula.

This means that fuel consumption tends to look too good.

It is the vehicle manufacturer’s job to keep these tolerances under control. For us, however, it is interesting to know the tendencies.

In the case of passenger cars, the control of the distance parameters is not so strict. Significantly larger errors must be expected.

The fuel consumption value from the vehicle display

Modern vehicles offer an alternative to writing down and calculating.

With these vehicles, the fuel consumption value can be read directly on the display instrument. Telematics systems even transfer the data directly from the vehicle to the computer in the office.

But even this value is not without inaccuracies.

One would imagine that there is a flow meter installed somewhere, which, like a water meter, measures the flow of fuel.

But this is not the case.

Such measuring systems are available for retrofitting. I know, that those systems are used in vehicle development, where fuel consumption is really meticulously analyzed by engineers.

The fuel consumption values from the display are not measured values, they are calculated by the engine electronics.

There was a time when a diesel engine could do without any electrics or electronics. It didn’t even need a spark plug.

The times without electronics are long gone.

The diesel engine still does not need spark plugs, but the previously purely mechanical, hydraulically controlled injection is now electronically controlled.

Thanks to modern engine control, it has been possible in recent decades to drastically reduce fuel consumption while at the same time minimizing pollutants in the exhaust gas.

As a by-product, the vehicle can also calculate and display fuel consumption.

How accurate is the injection quantity?

The basis for this consumption value is the fuel injection quantity in the engine map.

The engine map is a database stored in the engine control unit, in which for each engine operating point the ideal operating parameters are stored.

These parameters are not only the injection quantity but also the injection time and the injection process. (Playing around with this map is called “chip tuning”)

The engine electronics permanently measures innumerable state variables in order to determine the current operating point.

It then takes the driver’s request and determines the parameters that lead to the desired driving condition. It takes a quick look at the engine map and gives the injection system commands for the perfect injection process.

This is a highly dynamic process while driving. The engine very very rarely has the chance to run stationary. Actually, it’s close to never! There is always something changing in the driving situation.

These calculations run in real-time.

The displayed fuel consumption is based on the injection quantity determined by the engine control unit. In reality, the actually injected amount of fuel differs slightly from the calculated amount.

It is not certain whether exactly the amount of diesel, that was ordered by the electronics, runs through the injection valve.

Many factors play a role that cannot be precisely controlled, e.g. flow resistance, dead times, inertia, vibration processes in the system, etc.

And of course the diesel temperature again. The engine actually cares about the diesel mass because it correlates with the chemical energy and determines the power output. When it comes to fuel consumption, however, we calculate in liters. The motor electronics orders in grams and we get information in liters delivered.

Since the injection process takes place very frequently, these minimal deviations can add up to noticeable magnitudes.

You have to be aware:

If a six-cylinder engine rotates at 1000 revolutions per minute, that is 3000 injections per minute, i.e. 50 injections per second!

The vehicle manufacturers correct these errors with correction factors in the consumption calculation.

As a rule, however, this does not lead to absolute precision, since these errors change over time and with the operating point.

The fuel consumption value from the telematics system

Telematics systems usually show the values of the vehicle’s consumption calculation programmed by the vehicle manufacturer!

The correction factor set by the vehicle manufacturer’s engineers, therefore, has the same effect on all telematics systems.

In this case, there is no “independent” measurement by a non-manufacturer telematics system.

To say it again clearly:

Even if a manufacturer-independent telematics system is used, the consumption values are not necessarily manufacturer-neutral. Therefore, despite the independent fleet management system, the errors are vehicle and manufacturer-specific and the consumption values must not be compared with one another without being checked.

A really good telematics system should double-check the value of the vehicle with the fuel bill.

You should also check the values from the vehicle or fleet management against the values based on refueling.

Summary

Please look up also the other articles in the category Fleet Monitoring. There you will find even more helpful info.

For calculation of the scatter of your consumption value please refer to the article “average consumption”. This calculation will give the range in which the fuel consumption calculation result could deviate. If you want to go even more in detail the article “Scattering” is the resource.

Still questions open? Please write them in the comments box or send me a message.