Factors that influence the effectiveness of EcoRoll — A deep insight

The effectiveness of the EcoRoll functionality depends on the operating conditions, and the vehicle itself.

That message is pretty clear, and that’s why the EcoRoll feature on trucks is so controversial.

Everyone has different experiences with the function. Sometimes it saves fuel, sometimes it doesn’t.

I admit it is not a simple matter to understand what exactly is causing this fluctuation, and therefore it is easy to get frustrated.

In this article, I explain the influencing factors in detail. This will give you a better understanding of the variability and help you to use the function better.

All estimates in this article are based on an average European 4×2 tractor-trailer combination. If you are interested in different configurations, let me know in the comment, and I will try to help.

For general information on the EcoRoll function, please refer to the article: EcoRoll – Unraveling the mysterious freewheel function.

Without further ado, we can start right away.

Factor: Altitude profile of the route.

The overall effectiveness of EcoRoll depends on the number of EcoRoll events on the route, and the amount of consumption savings per EcoRoll event.

The number of EcoRoll events correlates with the number of inclines and declines, i.e., the number of hills on the route.

Deceleration due to traffic obstacles is usually less frequent and consequently has a lower potential for savings.

If the road is very flat, EcoRoll is usually not effective. The same applies, if you are driving in terrain with steep hills.

I say “usually” because there are a few tricks to save a drop or two even in these driving situations.

However, I will not go into these details here. One of these tricks is “Pulse and Glide”. I will explain the function in a separate article.

So let’s see what kind of topography has a beneficial effect on the effectiveness of EcoRoll.

The ideal number of EcoRoll events per route.

A large number of successive moderate hills is an important prerequisite for an effective EcoRoll. The more hills, the greater the saving.

For effective EcoRoll, the truck must roll a certain distance in EcoRoll mode to allow a speed differential to build up and decay. This has an impact on the optimal number of hills that fit a given distance.

Realistically, you only have a limited speed range, as the lower and upper speeds are restricted.

The acceleration during a downhill run depends on the downhill force and thus on the gradient. This means that the gradient is decisive for the distance and time required to exploit the full speed range.

The optimal number of hills, therefore, depends on the inclination angle of the road in combination with the length of the slope.

Ideally, the next incline always starts exactly at the point when the vehicle has reached maximum speed.

We cannot change anything about the road topography. However, it is essential to understand what to expect from the EcoRoll function on the respective route.

Rarely will the tour be on routes with the optimal number of hills. Sometimes the hills will be too short, sometimes too long.

So, to make a fair assessment of the EcoRoll mode, you have to ask:

On which slope does a truck roll at a constant speed?

This question is relevant because if the truck does not build up speed, even when rolling freely, the EcoRoll function will not work as described above.

A fully laden forty-ton truck rolls at a constant speed (80 to 90 km/h) in EcoRoll mode if the gradient is approx. 1%.

1 % slope is a little more than half a degree angle, which is relatively little.

1% means that the road overcomes a difference in height of 1 m on a horizontal stretch of 100 m. This is so little that you can hardly see it with the naked eye.

This value depends on the vehicle’s weight and the magnitude of the driving resistances. Therefore, the value of 1% is, of course, only a guideline value, which is different in every specific application.

We will look at it in detail in a moment.

The truck without EcoRoll needs approximately 0.2% (0.1°) more angle to roll downhill with constant speed.

For predictive driver assistance systems, the sensitivity to small angles means, that the map in the vehicle must be very accurate, otherwise, the EcoRoll function cannot achieve its full potential.

Experience has shown, that a measured map must be used. Recording data from the truck while driving is not accurate enough. Today, it is state of the art, to equip the truck with a preloaded precise map and then refine it over time with data recorded while driving.

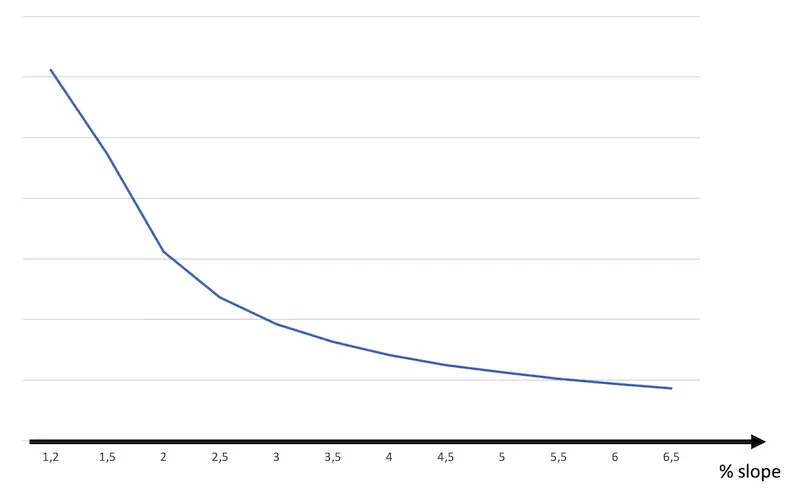

Effect of the angle of inclination.

The angle and length of the slope in connection with the following uphill gradient have a significant influence on the effectiveness of EcoRoll. So let’s dive deeper into this matter.

Since I want to evaluate the effect of an influencing factor on the effectiveness of the EcoRoll function, I have to make a comparison.

As a basis for comparison, I use the same truck and the same operating conditions, but with the EcoRoll function switched off. I only ever change one factor to isolate the effect.

In order to recognize the influence of the road gradient, I have made some additional assumptions that do not exist in reality. That’s why you can’t take the curve too seriously. It only serves to illustrate the effect of a single parameter.

I have assumed, that each slope has exactly the length at which EcoRoll can utilize the complete speed tolerance. So the terrain is perfectly chosen for EcoRoll.

For each angle, the length of the slope is different. Because, as I said above, the angle, and the length of the slope correlate.

The truck without EcoRoll, which is used for comparison, has the same length of slope available. After all, it is going down the same hill.

You can easily see that small inclinations offer the greatest potential for savings.

What’s the reason?

On a given slope angle and length, the excess potential energy is the same for both driving scenarios (with and without EcoRoll).

On small slopes, the acceleration is lower due to the lower downhill force. This results in a greater distance being required to reach the upper speed limit.

Distance times engine braking force gives the amount of waste heat generated by the engine. The longer the distance, the more energy ends up as waste heat.

EcoRoll avoids this bad energy conversion.

Therefore, EcoRoll makes a bigger difference on gentle slopes than on steep ones, where the distance of acceleration is less.

Let us now look at the different inclinations in detail.

Slopes around and slightly above 1 % are particularly advantageous for EcoRoll.

In these conditions, the truck with EcoRoll keeps the speed constant or increases it very slowly. The truck without EcoRoll slows down because of the retarding engine.

There are different strategies for the truck to tackle a slope, which is too flat for constant speed rolling:

- Enter at high speed, then slow down, and then accelerate again.

- Keep the speed constant with low engine torque. (Sometimes, it might not even be possible for the engine to deliver this little force.)

- Drive over the hilltop at a low speed and then accelerate downhill.

If the slope angle allows EcoRoll to roll with constant speed or accelerate, EcoRoll always has an advantage.

This is a common and lucrative driving situation for EcoRoll.

There are two other favorable aspects:

So the hills can be long without the risk of having to brake.

Patience is needed here for an effective EcoRoll.

Despite the low gradient, you must enter the gradient at a low speed. This means that you have to let off the throttle very early on uphill.

Then let it roll patiently from incline to decline and back to incline until the speed has dropped back to the lower value.

I use a speed range between 80 and 90 km/h for my estimates.

A good, anticipatory cruise control system calculates the optimal starting speed for the EcoRoll Event from the knowledge of the length and gradient. This way you don’t lose time unnecessarily and still achieve the maximum savings effect.

The entire possible velocity range is rarely used here, since slopes that long tend not to occur in reality. (Imagine that with the angle of inclination for the constant speed, the incline would have to be infinitely long).

In the range of up to 2% slope angle, the effectiveness is good.

In this range of angles, the perfect EcoRoll route is still very long. However, there is a real chance of encountering it in reality and being able to use the full-speed range.

Even if in reality your slope is shorter than the optimal length, you can expect noticeable consumption effects.

In these scenarios, the largest speed difference between the two trucks (with and without EcoRoll) builds up. Therefore, the relative advantage of EcoRoll is large.

In the range from 2% to 3% slope, the saving potential decreases.

Here, the length of the optimal slope is in a very realistic range.

This bears the risk that these hills are longer than desired. In this case, the upper-speed limit would be exceeded.

These hills may not be driven on with EcoRoll, so some hills could be lost for the EcoRoll mode.

Even if the slopes are short enough, the EcoRoll efficiency advantage decreases because the vehicle without EcoRoll also accelerates strongly and thus reaches a high final speed.

There is not much to gain in the area above the 3% slope.

On a gradient of more than 3%, a forty-ton truck builds up speed very quickly, even in coast mode with gears engaged.

The likelihood of these hills being too long increases as the gradient increases.

Therefore, often on these hills, EcoRoll will not be activated.

Even if the length of the slope fits, the ratio of motor braking force and slope downforce changes to the disadvantage of EcoRoll.

The maximum speed difference between EcoRoll and without EcoRoll becomes smaller and smaller, and so does the saving.

Effect of the length of the slope.

Too long slopes are bad for EcoRoll.

If the length of the slope is such that the maximum speed is exceeded, EcoRoll must not be activated.

On these sections of the track, coasting with the diesel injection switched off is more efficient!

If EcoRoll is used incorrectly on hills with high inclination, additional consumption may occur!

By the way, if the traffic situation forces you to apply the service brake during an EcoRoll Phase, it causes also additional consumption. Because you invested in idle consumption to preserve the energy, which you waste now during the braking time.

Too short slopes are not a problem.

If the slope is short, so that maximum speed is not reached, then only the amount of saving is reduced.

There is no danger of bad consumption.

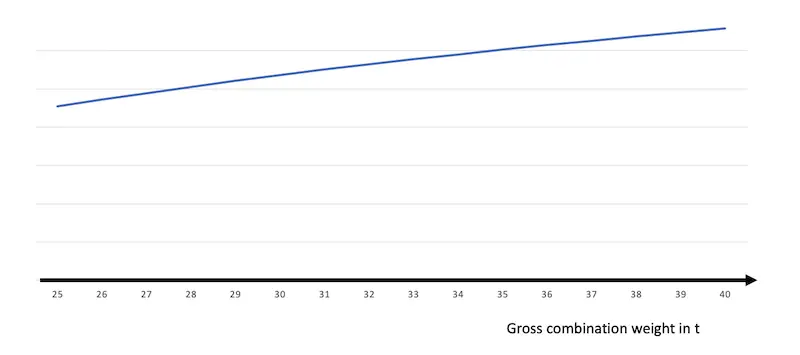

Factor: Vehicle weight

Mass is a determining factor for the amount of kinetic and positional energy that is stored in the vehicle.

For this reason, it naturally has an influence on the EcoRoll fuel saving potential.

Impact of the weight on the same slope angle and same slope length.

In order to understand, what happens under this circumstance, I explain it step by step.

On the same slope angle and length, the excess potential energy is the same. If the weight is less, the potential energy is less as well. However, it makes no difference whether the truck has EcoRoll activated or not.

Since the waste heat depends on the engine brake force and the distance, and the distance is fixed, the amount of waste heat is the same. It does not depend on the vehicle’s weight.

The difference, however, lies in the time it takes the vehicle to cover the given distance.

Less vehicle weight gives less downhill force and this results in smaller acceleration.

This means, that reducing the vehicle weight increases the duration of the EcoRoll time.

Increasing EcoRoll time increases idle consumption because the amount of fuel consumed during idling is a function of time.

More time in EcoRoll at the same slope eats away a bit more of the spared engine retarding work.

As the total vehicle weight increases, the consumption saving potential of EcoRoll increases as well.

Impact of vehicle weight on the usable topographies.

There is a second effect, that I need to talk about.

It is the effect of vehicle weight on the limits of usable topography.

This means, with lower GCW you lose some potential at flatter hills, but at the same time you gain some potential at the steeper side.

Unfortunately, I don’t have any data on whether or not the two effects cancel each other out.

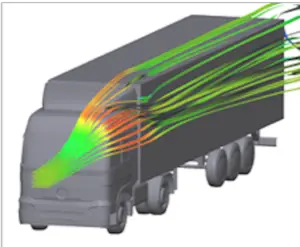

Factor: Rolling and air resistance

Rolling resistance and air resistance are the two driving resistances that continuously draw energy from the vehicle. Therefore, efforts are always being made to reduce them.

Working on the reduction of the driving resistances should be done independently of EcoRoll, but it also has an influence on it.

These two driving resistances together with the acceleration resistance are in balance with the slope downforce.

Impact of the resistance on the same slope angle and same slope length.

Again, the excess energy is the same, as well as the engine retarding work, which is responsible for the waste heat.

This time, even the downhill force is the same.

The difference here lies in the counterforce to the downward force.

When the driving resistance is lower, more power is available for acceleration, which shortens the EcoRoll time.

The vehicle with less driving resistance builds up speed more quickly, and this reduces idle consumption.

The reduction of rolling resistance and aerodynamic drag improve the overall fuel economy, and increases the effectiveness of EcoRoll.

Correlation of vehicle weight and rolling resistance.

I would like to point out here that rolling resistance and vehicle weight are interdependent.

Since rolling resistance depends not only on the rolling resistance coefficient but also on the wheel load, less load also means less rolling resistance.

Lower vehicle weight reduces the EcoRoll advantage, but at the same time reduces rolling resistance, which in turn has a positive effect on EcoRoll.

Impact of less driving resistance on the usable topographies.

When the driving resistance is lower, the minimum, as well as the maximum slope angles, become smaller.

You gain at the low end and lose at the high end.

With lower driving resistance, the optimum length of the gradient is smaller for the same angle. The vehicles accelerate more rapidly and therefore reach the upper speed limit in a shorter time and distance.

Longer hills drop out of the EcoRoll range, while the saving on shorter hills increases.

How this affects the effectiveness of EcoRoll depends on the concrete route. That’s why I can’t make any predictions.

Factor: Idle consumption

The idle consumption of the engine has a significant influence on the EcoRoll savings potential.

Ideally, the engine should be off during the entire EcoRoll phase. I call this function “EcoSail” and write a separate article about the difficulties involved.

Idling consumption must be as low as possible.

It is the task of the engine developers and manufacturers to realize this.

But vehicle engineers can also make their contribution to low idling consumption with a clever operating strategy.

Influence of reduced friction

Reducing the friction of all moving parts in the engine is a proven way to optimize engine efficiency. It helps not only with idle consumption, but with fuel consumption in general.

A well friction-optimized engine, therefore, saves in both operating situations, during the fired cycle, and during the EcoRoll phase, through lower idling consumption.

However, the engine braking work in coasting mode is also smaller, which works against the EcoRoll advantage.

I think we accept that because less fuel is consumed in both cases.

Influence of the auxiliary devices.

Auxiliary devices supply vehicle systems with energy.

These systems are either required for the operation of the engine itself or are needed for driving.

The following are necessary for the engine:

- the oil pump

- the coolant pump

- the fan for engine cooling

- the injection pump

Required to drive:

- the air compressor for the brake

- he power steering pump

- the alternator

- the air conditioning compressor

All these components draw energy from the engine and thus influence idling consumption.

To keep idle consumption low, auxiliary units should be switched off as far as possible during the EcoRoll phase.

Some auxiliary systems are uncontrolled, so they are always running.

Others have a control system and are only switched on when required.

To reduce consumption, all auxiliary consumers should be equipped with a control system, which was not the case in the past.

You may have read about a controlled water pump or a controlled power steering pump. As a general rule, an additional clutch is installed between the engine drive and the auxiliary unit, which can be disengaged by a clever algorithm.

These components are expensive, and therefore manufacturers naturally make a cost/benefit assessment before deciding for or against such a component.

For EcoRoll, it is interesting that some vehicle systems have a storage capability. These systems can be charged when energy is free or cheap. If they are sufficiently charged, the auxiliary consumer can be switched off during EcoRoll.

What does that mean in concrete terms?

If you are driving down a steep gradient, where you have to brake anyway, the air compressor, AC compressor, and generator should be fully engaged.

This means that the surplus energy is stored in the vehicle systems and therefore remains in the vehicle. This energy is still usable at a later time.

During the EcoRoll phase, these consumers should not be switched on under any circumstances, as this increases idle consumption.

Since steep hills are not always available, these systems must also be charged during the fired run. Best in the situation when the engine is running at maximum efficiency.

As you can see, it’s not easy and requires foresight of what will happen in the next few kilometers. That’s where the manufacturer can show what he’s got.

Optimizing such a control system in terms of both, demand and fuel consumption requires diligence, skill, and effort.

Usually, you will not notice anything, but you can measure the result in fuel consumption.

I will go into more detail in other articles.

Influence of thermal engine efficiency

Engine efficiency is the source of the savings tapped by the EcoRoll function. Do you remember the red bar at the top of the graph?

The worse the engine efficiency, the greater the EcoRoll effect.

The motor efficiency is not always the same!

It changes depending on engine torque and engine speed.

In a diesel engine, the area of best efficiency is at high engine torque. In common parlance: at full load.

Conversely, it means that poor efficiency occurs at low engine torque.

Relatively much of the burnt diesel is converted into waste heat, and relatively little is used in the drive.

This is another reason why the EcoRoll savings are highest on very slightly sloping roads.

Here, the downhill force helps when driving downhill. The engine, therefore, has to do very little work and runs with a low load. These are operating conditions with poor engine efficiency.

If the vehicle runs into a flat incline after the downhill slope, then poor efficiency will have an effect for a long time.

If the vehicle runs into a steep incline, then a better efficiency acts for a short time. This means that less waste heat is generated.

The flatter the road gradient, the poorer the engine efficiency without EcoRoll and the greater the EcoRoll advantage.

When driving with EcoRoll, you trade the poor engine efficiency at low load for the not-so-bad idle consumption. This brings us to a very important balance:

High idle consumption on the one hand and better engine efficiency on the other reduces the EcoRoll effect.

The former is bad, the latter we can live with because it absolutely improves consumption.

Conclusion

So, now you have learned under which conditions EcoRoll saves and under which conditions nothing can be gained. You also know what optimization options the vehicle manufacturers have.

Please write me your experience with EcoRoll in the comments! Did the explanation help you?

All estimates and trend descriptions in this article are highly approximated, just to explain the dependencies and give a sense of scale. For more precise information, measurements, or computer simulations must be performed in the specific application.