Demystifying Pulse and Glide -Unraveling a Secret of Fuel Saving

With Pulse and Glide, we are dealing with a function that does the opposite of what you learned in driving school.

What do I mean by that?

Well, the driving instructor taught you to keep the throttle very still and not to constantly fidget back and forth. But that’s exactly what Pulse and Glide does.

Why should that save diesel all of a sudden now? Has physics changed in recent years?

— Of course not! —

In this article, you will read how Pulse & Glide works and when and why it saves fuel.

With this, you can then judge for yourself whether this function is interesting for you.

When you first employ the Pulse and Glide driving strategy, it might take some getting used to – to put it mildly.

Did you wonder why I chose this particular picture of a straight, lonely road for the article?

Well, it’s because this very scenario sets the stage perfectly for Pulse and Glide to unleash its true capabilities.

You’ll see no trace of traffic in sight, no hindrance to impede your driving strategy.

Granted, during typical working hours in Germany, such an idyllic situation may not be the everyday norm.

So let’s take a close look at how Pulse and Glide work.

What is Pulse and Glide?

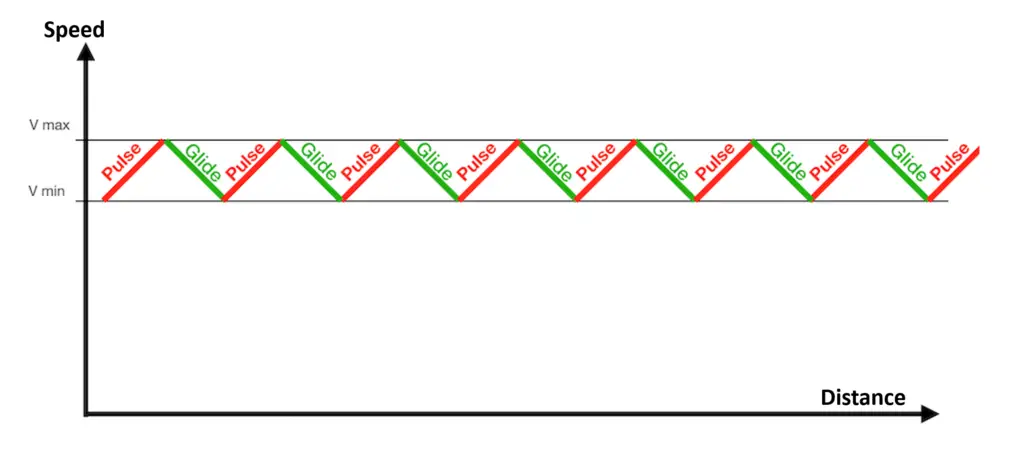

Pulse and Glide in a diesel truck is a driving strategy in which the vehicle is charged with kinetic energy through an acceleration process and then dissipates this energy in a rolling phase.

This process is repeated cyclically, with the travel speed oscillating between a lower and an upper limit.

The goal is to improve engine efficiency by Load Point Increase.

You can think of Pulse and Glide as an extension of the EcoRoll function.

I have explained in detail how EcoRoll works in the EcoRoll – article. It will be helpful if you read it.

While EcoRoll uses position energy in hilly terrain to propel the vehicle, Pulse and Glide extend EcoRoll’s range of action to flat roads.

It’s not excess positional energy that feeds the forward motion here, but it is kinetic energy generated specifically for that purpose.

However, Pulse and Glide is not necessarily bound to a vehicle function. This driving strategy can also be used manually.

If your truck does not have this function, you can also implement the Pulse and Glide driving strategy with your foot on the accelerator pedal.

You can read more about how to do this below.

But you definitely need to have EcoRoll enabled!

For vehicles that only offer EcoRoll in cruise control mode, manual pulses and guilds are not so easily implementable.

Of course, it’s much more convenient if the truck’s cruise control does it automatically. This is not in question.

What does Pulse and Glide do?

As the name suggests, the driving cycle consists of two phases:

- a drive phase “Pulse” and

- a rolling phase “Glide”.

The Pulse Phase is an acceleration phase.

In the Pulse phase, the vehicle accelerates with a high engine load.

The velocity steadily increases, leading to a rise in the vehicle’s kinetic energy.

As a matter of fact, the vehicle acts as a storage device for motion energy, accumulating kinetic energy.

During this acceleration process, increased fuel consumption occurs due to the additional acceleration resistance.

Even with the higher fuel consumption, the engine operates more efficiently during the acceleration phase compared to driving at a partial load without acceleration.

The Glide phase is a rolling phase.

In the Glide phase, the truck rolls in EcoRoll mode with the engine idle.

The inertia of the vehicle acts as the driving force in this situation.

Obviously, the velocity steadily decreases, as the additional kinetic energy, stored in the vehicle, is converted into drive work and serves the air and rolling resistance.

In fact, the engine does not have to provide any drive work at this distance.

During the glide phase, idle consumption (typical of EcoRoll) occurs. Fuel consumption is very low during this time.

Are you interested to learn, why the engine doesn’t switch off? Then you need to read the next article.

At the end of the glide phase, the vehicle again has a speed reserve for accelerating.

How does Pulse and Glide save diesel?

Pulse and Glide saves fuel because a diesel engine is more efficient at high engine load than at low engine load.

The load increase due to acceleration resistance, in conjunction with a subsequent rolling phase, results in better overall consumption than constant driving with a low engine load.

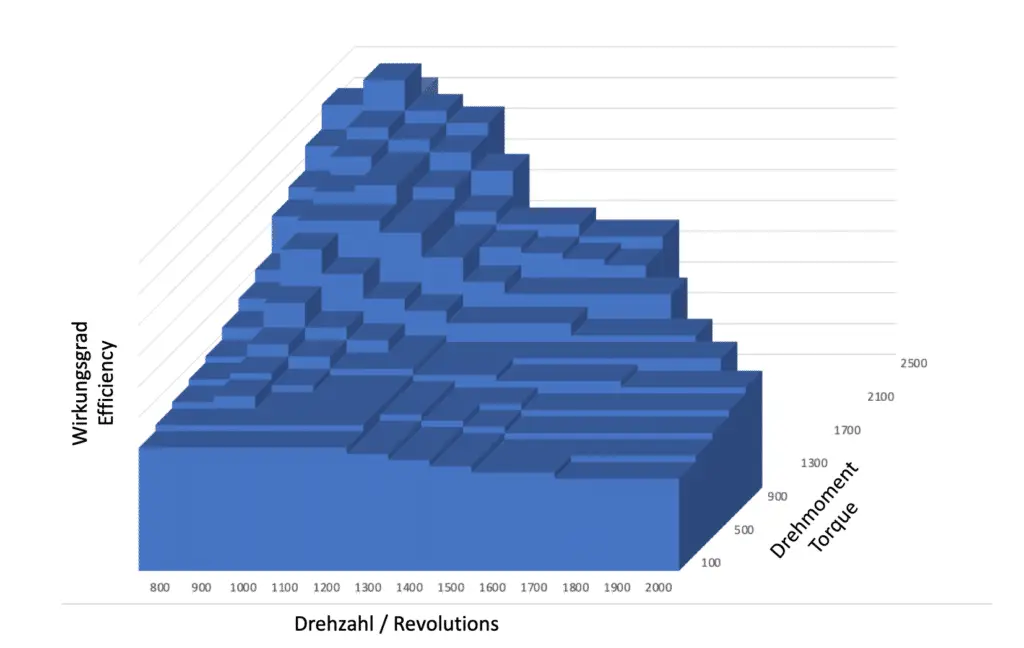

To understand this even better, let’s look at the efficiency map of a truck engine.

How the efficiency map of a diesel engine looks like.

Unfortunately, I am not able to share a genuine efficiency map of a real diesel engine. For this reason, I have created an exemplary 3D diagram, on which I explain the essential points.

- In the diagram, you find the engine speed from left to right. On the far left is the idle speed and on the far right is the governor speed.

- The engine torque runs into the depth. The maximum engine torque at the respective rpm is the limit. That is why there are fewer bars in the high-speed range. The motor simply has less torque there.

- The height of the bars indicates the efficiency at the respective operating point. Higher bars represent better efficiency.

As you can see, the area with the highest bars is relatively small.

That’s the area of interest. There is the best efficiency.

The best efficiency for a truck diesel engine is at a relatively low rpm and high torque.

In both directions, with lower torque and higher speed, the efficiency deteriorates, and the bars become smaller.

How to match the driving speed range with the range of good engine efficiency?

When you envision an engine with good fuel economy, your initial thoughts may lead you to imagine an engine with highly efficient combustion and minimal mechanical friction.

However, that perception is not entirely accurate.

Having an engine with excellent efficiency at one specific operating point serves no practical purpose if the engine rarely operates at that particular point.

Engine developers invest significant diligence and effort in enlarging the engine’s high-efficiency range to the maximum possible extent.

By doing so, they aim to broaden the target area in which the engine operates with exceptional efficiency, optimizing its performance across a wider spectrum of driving conditions.

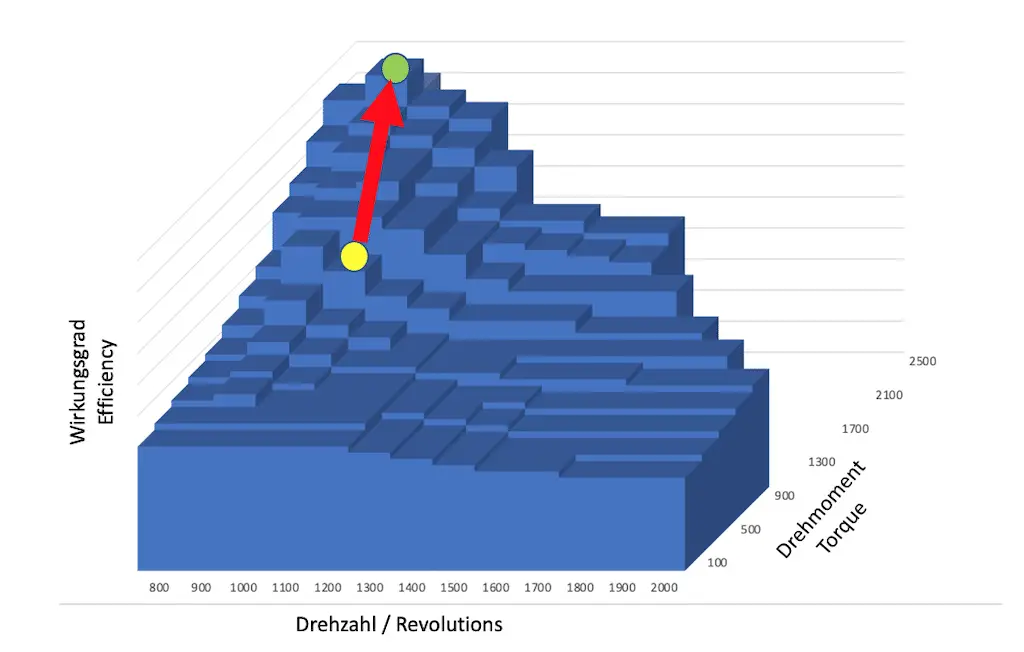

Next, the operating point of the engine needs to be shifted into this range during travel.

For this purpose, the engine’s rpm should be as low as possible at cruising speed.

For many years, you can observe a trend towards ever smaller axle ratios.

An approach referred to by the technical term “down speeding”.

Pro and Con of downspeeding

A “long axle” (this is what we call small and thus fast axle ratios) results in a lower engine speed at the same driving speed.

At the same time, it results in higher engine torque, even though the driving force at the wheel is the same.

This shifts the engine’s operating spot into the field of better efficiency.

However, there are limits to this optimization.

Above a certain axle ratio, the maneuvering speed becomes too high when there is a need for slow driving. In addition, the vehicle becomes lazy when accelerating.

You also need some torque reserve so that you don’t have to downshift on every little incline.

We’ll take a closer look at down speeding as a consumption optimization in another article later.

At this point, it should be said that the range of maximum efficiency can not be reached by conventional means of down-speeding.

There are several, unconventional ways to achieve it anyway. One is Pulse and Glide.

I use a constant speed scenario as the reference for comparing the effects of Pulse and Glide here in this article.

In order to understand, where the efficiency gain of Pulse and Glide comes from, we need to understand the concept of load point increasing.

What is load point increase?

Load point shifting (load point increasing) is the improvement of the efficiency of an internal combustion engine by increasing the engine torque beyond the required drive torque.

In this procedure, electrical or kinetic energy is generated in addition to the drive work.

The concept of load point increase is based on a simple idea.

These two forms of energy are characterized by the fact that they can be converted into drive work with almost no loss.

The basic idea comes from the hybrid drive.

Since this type of drive has a large battery and a powerful electric motor/generator, it is possible to store a lot of electrical energy.

Such a hybrid drive is an expensive matter because there are two drives in the vehicle.

If you have already made this investment, then of course you will use load point increase to produce the maximum fuel-saving effect.

That’s why every modern hybrid drive works with load point increase.

The engine thus charges an energy storage device very efficiently during the pulse phase with its torque reserve.

When the accumulator is full, the engine is disconnected from the drive and the energy from the accumulator provides drive power until the accumulator is empty.

You use the stored energy to propel the vehicle at a later time.

How to store energy without a battery?

Even without a hybrid drive, you have a way to store energy.

This is a very cost-effective variant of load point increase. Basically, there are no additional costs associated.

However, it only comes at the price of fluctuating driving speed, which admittedly is not everyone’s cup of tea and cannot be realized in every traffic situation.

Let’s take a deeper look at this.

Imagine you are driving on the road in the picture at about 80 km/h for one kilometer.

If you drive on a level road at the same speed and with the same vehicle weight, then the driving resistance is constant.

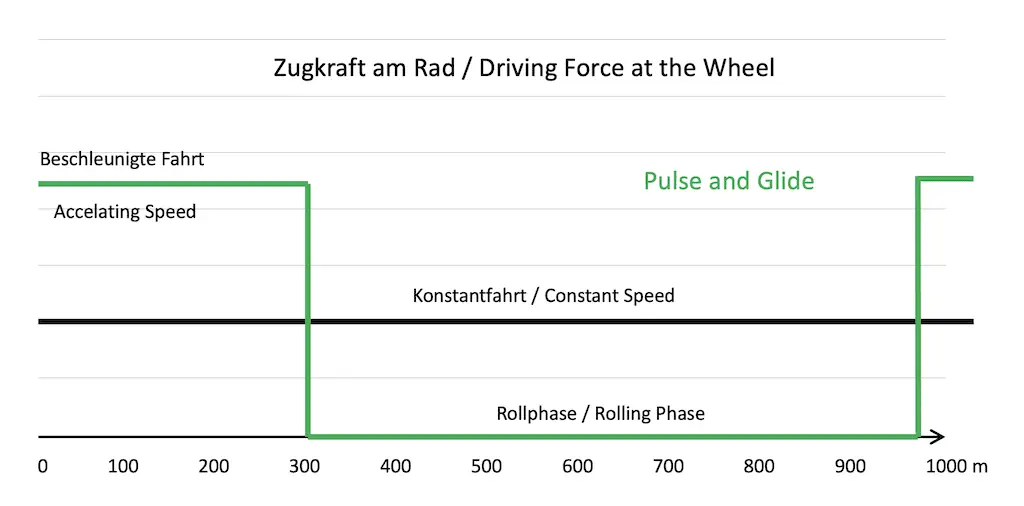

What is the drive wheel’s traction force curve?

If you drive the distance at a constant speed, the tractive force on the wheel is exactly equal to the magnitude of the driving resistance. The forces are in equilibrium.

As an example, I am going to use the default values of my driving resistance calculator.

It says, that the driving resistances are in the range of 3,5 kN.

With this driving force, the required engine torque will be in the range of 700 Nm, depending on the tire diameter and the axle ratio.

That’s not a lot for a full-blown truck engine, it is just about 28%.

Even if you go 90 km/h the driving resistance would go up by 15% to 3,9 kN and the engine torque to 800 Nm but still only use 32% of the max. engine torque.

With Pulse and Glide, you now go full throttle.

Let’s say your engine has 2500 Nm of maximum torque, then 12.5 kN is now applied to the wheel.

The vehicle will accelerate from 80 km/h to 90 km/h in 12 seconds (285 meters).

When the maximum speed is reached, you have to let off the gas. At this moment, the transmission switches to EcoRoll. The inertia force now works directly against the driving resistances.

Because the wheels roll freely, the speed drops slowly. With my input data in 30 seconds (730 meters) back from 90 to 80 km/h.

This should only give you a rough idea of the order of magnitude. You can make much more precise calculations with your real input data. Above all, the drive train efficiency must actually be taken into account. I have omitted it here for simplification.

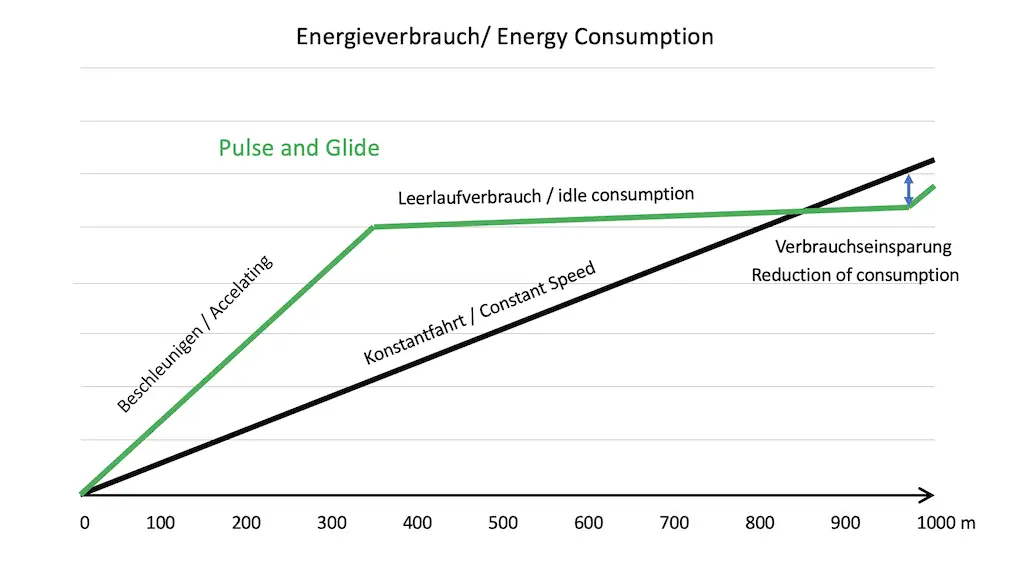

What is the energy consumption curve over this distance?

Constant Speed Driving.

At constant speed, the energy consumption is made up of the drive work and the heat loss.

The driving work is calculated as the constant drive force times the increasing travel distance. Given that the energy is equal to the mechanical work, therefore, the energy consumption increases constantly with distance.

The heat loss is also the same and depends on the engine’s efficiency. As the drive work increases, the heat loss also increases.

Both combined result in the black curve.

Pulse and Glide Driving.

In the first driving section with Pulse and Glide, practically the same applies. The major difference is that the drive work is significantly greater. A much larger tractive force is applied for accelerating the vehicle.

The heat loss is also bigger. However, the motor efficiency is better.

Better engine efficiency means that energy consumption is lower at the end of the acceleration phase than at the end of the travel distance at a constant speed.

From the moment you let off the throttle, the engine idles. Idling consumption during rolling road eats up some energy you just saved.

During the rolling phase, therefore, only a very, very small amount of diesel is consumed, because the mass of the vehicle returns the previously stored energy without loss.

Lastly, we have to talk about what determines the amount of savings at the end of the rolling phase.

In which driving situations does Pulse and Glide save?

When you’re driving on the road alone.

Traffic density is certainly an important factor.

If you are not the master of your driving speed, because you have to adjust it again and again to the traffic, then Pulse and Glide has no chance.

Truck columns on your freeway lane cannot be mastered with Pulse and Glide.

Imagine that there would have to be an agreement that all trucks accelerate and roll evenly.

— It is not very likely that this will work at all. —

By the way, it is not even possible, because the topography, different loads, rolling resistances, motorization, etc. stand in the way of the same acceleration and the same coasting of several vehicles driving behind each other.

Of course, you are free to take out the speed by a rolling phase and let the vehicle in front drive away. Then you have room for acceleration.

Your fellow driver behind you will be surprised. He may try to overtake you, but then you’ll already be accelerating again.

You won’t make any friends with that.

I’ll stick with it:

So, Pulse and Glide only bring potential savings if you can determine your speed independently of other vehicles.

On German highways, this probably won’t happen very often. But there are other areas where truck traffic is on the road.

If the road does not slope or slopes very slightly.

In the considerations so far, I have assumed a level road with no gradients or inclines. This is a good prerequisite for Pulse and Glide.

What happens if the road has a slope and thus the gradient resistance comes into play?

Let’s see where the limits of effectiveness are, then.

The road goes downhill.

It is also logical. If no drive power is needed at all, then the throttle should not be opened.

If the slope of the hill is so small that the vehicle slows down in EcoRoll mode.

In these cases, the required tractive force at constant speed is lower than when driving on level roads, and thus the engine torque is further away from the range of optimum efficiency.

Even if little fuel is injected here and thus fuel consumption is low, the efficiency of the engine is nevertheless particularly poor.

Here, it is possible to accelerate quickly to the maximum speed with optimum efficiency. This is followed by a long rolling phase because, in addition to the kinetic energy, the position energy is also available for propulsion.

To sum it up, the vehicle accelerates faster and rolls longer in Pulse and Glide mode, while at constant speed the ratio from drive work to heat loss is more unfavorable.

The road goes uphill.

With smaller gradients, the pulse and glide potential decreases, because the distance between the operating point of the engine and the range of maximum efficiency becomes smaller and smaller. This reduces the savings potential.

The acceleration phase lasts longer, but the roll phase becomes shorter and shorter.

So uphill, there is little to nothing to be gained.

What factors affect the effectiveness of Pulse and Glide?

The engine efficiency map.

The shape of the motor efficiency map has a major impact on the savings potential of Pulse and Glide.

Engines are designed for a wide operating range with very good efficiency. The better this is achieved, the lower the savings potential of Pulse and Glide. Of course, this has limits.

To judge which engine is doing best, you need the real engine map diagram. However, this data is usually secret and therefore difficult or impossible to obtain.

However, it can be said that the rather poor engines have a greater potential for pulse and glide than the really good engines.

The basic vehicle setup.

The basic vehicle tuning determines the position of the operating point in the engine map at a constant speed.

I have already written about down speeding above. Down speeding is the shifting of the operating point into the range of good engine efficiency by using a fast axle ratio.

Every manufacturer has his own opinion on how far he wants to go.

However, if the operating range at constant speed is already very close to the range of optimum engine torque, then Pulse and Glide naturally has less potential.

You can tell by the fact that there’s not much torque left for acceleration.

Again, an optimized vehicle has less potential than a less optimized one.

The vehicle weight and rolling resistance.

Rolling resistance is determined by two relevant influencing variables:

- The rolling resistance coefficient of the tires and

- the wheel load.

There is therefore a relationship between the vehicle load and the rolling resistance.

The sum of the wheel loads is just as great as the total weight of the vehicle. The weight force must be transferred to the road via the tires.

Accordingly, the greater the vehicle weight, the higher the rolling resistance. It means more drive force is required and thus a higher engine load is involved.

Conversely, a lower rolling resistance means a lower required drive torque and thus poorer engine efficiency.

It’s kind of strange.

The vehicle weight and acceleration resistance.

However, the weight of the vehicle is also reflected in acceleration resistance and kinetic energy.

With a lightweight vehicle, more engine torque is available for pulses because the rolling resistance is lower. Acceleration is therefore greater and the maximum speed is reached more quickly.

In the rolling phase, less kinetic energy is available, so the truck does not roll as long despite lower rolling resistance.

The lower driving weight therefore causes shorter and therefore more pulse and glide cycles.

The speed and the air resistance.

Air resistance is also determined by two relevant influencing variables:

- The drag coefficient of the vehicle and

- the driving speed.

Unlike rolling resistance, however, the relationship is not linear, but quadratic.

The higher your driving speed, the faster air resistance increases.

In principle, the same applies to air resistance as to rolling resistance:

What role does the location and size of the speed range play in Pulse and Glide?

If you set the speed control range upwards, starting from your cruising speed, then the air resistance increases with each pulse process compared to constant travel.

Let’s say you’re going a constant 85 km/h without Pulse and Glide. With Pulse and Glide, your speed range is between 85 and 90 km/h. Then, of course, the average air resistance is higher than with constant speed.

To avoid this, you have to move the speed range down. So 80 km/h to 85 km/h. Then you win twice. But of course, you lose driving time.

For this reason, you will want to keep the speed range rather small. This will result in more Pulse and Glide cycles on the same track, but will keep the average speed high.

I think the most useful speed range depends on the driving environment.

Does Pulse and Glide work without EcoRoll?

What actually happens if, instead of using EcoRoll, you run the engine in coast mode with a gear engaged?

Well, you burn up the efficiency advantage that you gained during the Pulse phase in the engine brake during the Glide phase.

So that doesn’t produce the desired effect!

The gold standard would be EcoSail, where the motor stops when rolling. Unfortunately, this is not yet available for purchase.

Conclusion

I have tried to present the function and potential objectively. Hopefully, I have succeeded in doing so.

You have certainly noticed in the conclusion that I do not consider the real savings potential in real use to be particularly large. Please write to me if I’m wrong about that.

Please let me know in the comments what you think of this feature and if you know of any situations where Pulse and Glide can reach its full potential.

Sources:

Forsberg, David; Hall, Marcus (2019): Reduced Fuel Consumption of Heavy-Duty Vehicles using Pulse and Glide (online) https://liu.diva-portal.org/smash/get/diva2:1343144/FULLTEXT01.pdf (retrieved on 18.10.2021)